Teledyne Dalsa Machine Vision

Teledyne DALSA is a global leader in high performance digital imaging and semiconductor technology, headquartered in Waterloo, ON, Canada.

Odyssey Scientific Inc. is an authorized Teledyne Dalsa Representative

Designed specifically for factory floor deployment, Teledyne Dalsa's innovative vision technologies offer scalable solutions that satisfy a wide range of application needs, from positioning robotic handlers to complete assembly verification. These solutions include highly integrated 1D, 2D and 3D camera/imaging systems for single-point applications, embedded vision system controllers for multi point applications, and powerful vision software.

Visit Teledyne Dalsa for a full range of product information:

Engineered Products

Odyssey Scientific Inc has developed and deployed numerous custom designed inspection technologies including Body Contaminant Detection and Sealant Detection.

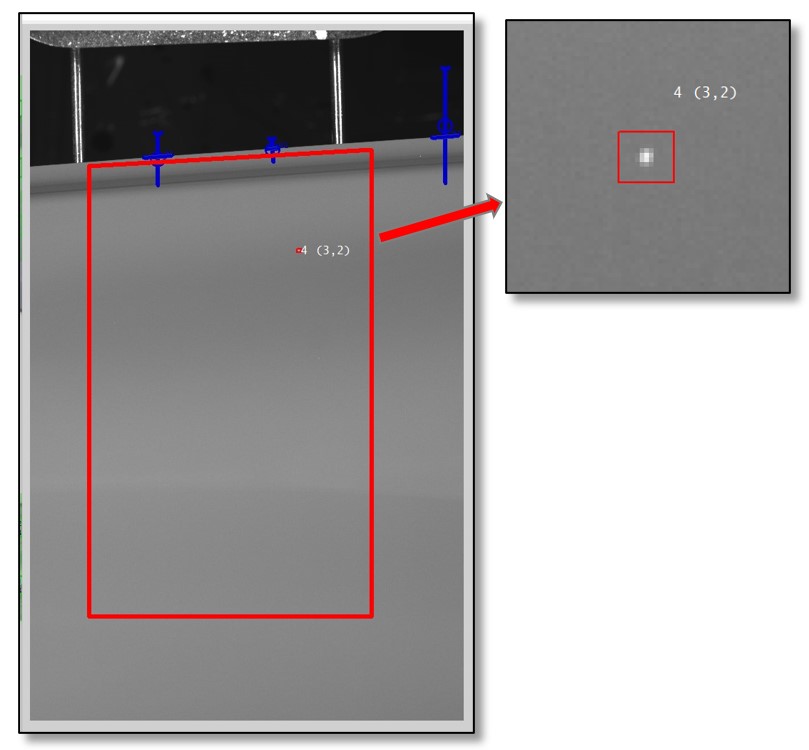

Body Contaminant Detection Technology

The Body Contaminant Detection Technology examines 3-dimensional vehicle surfaces to identify the presence of unwanted sealant drips during sealant processes prior to painting.

The technology utilizes customized lighting and high-speed, high-resolution imagers to cover large surfaces for inspection.

The technology inspects moving targets without the need to stop the process and is able to identify foreign contaminants on the surfaces prior to further processing.

Defects are identified to operators and process control equipment for remediation.

Repeatable defect recognition below 0.5 mm is achievable.

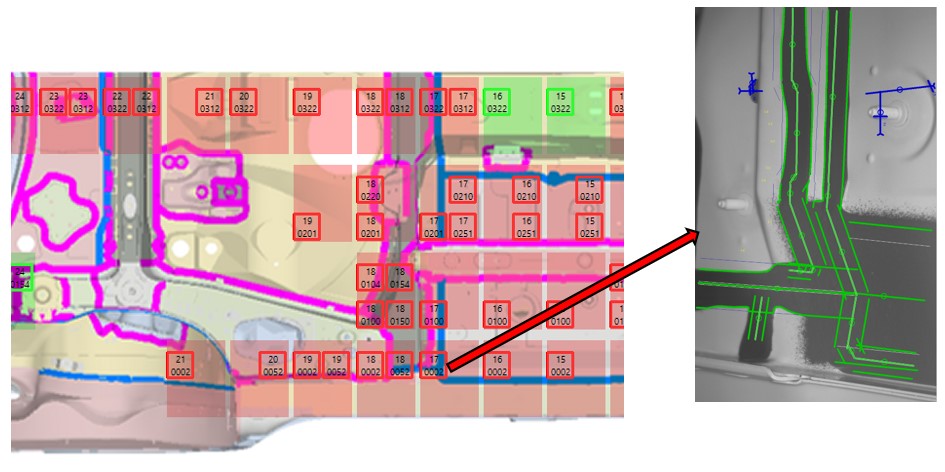

Sealant Detection Technology

The Sealant Detection technology examines 3-dimensional vehicle surfaces to determine the presence and integrity of sealant applied to cover seams.

The technology utilizes customized lighting and high-speed, high-resolution imagers to cover large surfaces for inspection.

The technology inspects moving targets without the need to stop the process.

Position locators identify position and the expected location of robot applied sealer. Measurement tools detect the presence, position and quality of the sealer application.

The technology can detect missing sealer beads, gaps and out of position application of the sealer beads.